O le uʻamea e le gaoia o le faʻapuʻupuʻuga o le uʻamea e teteʻe atu i le 'aisa, ea, ausa, vai ma isi mea e vaivai ai le 'aisa pe o le uʻamea e taʻua o le uʻamea e le gaoia; ma e teteʻe atu i mea e faʻaleagaina ai vailaʻau ('aisa, alkalis, masima, ma isi mea e faʻasusu ai vailaʻau) o le 'ele o le uʻamea e taʻua o le uʻamea e teteʻe atu i le 'aisa.

O le u'amea e le gaoia e faasino i le ea, ausa, vai ma isi mea e vaivai ai le 'aisa ma 'āsi, alkalis, masima ma isi mea e vaivai ai le 'aisa o le u'amea, e ta'ua fo'i o le u'amea e tete'e atu i le 'aisa. I le fa'atinoina, e masani ona vaivai le 'aisa o le u'amea e tete'e atu i le 'aisa e ta'ua o le u'amea e le gaoia, ma le u'amea e tete'e atu i le 'aisa e ta'ua o le u'amea e tete'e atu i le 'aisa. Ona o le eseesega o le tuufaatasiga o vaila'au e lua, o le muamua e le o lona uiga e tete'e atu i le 'aisa o vaila'au, ae o le mulimuli e masani lava o le u'amea e le gaoia. O le tete'e atu i le 'aisa o le u'amea e fa'alagolago i elemene fa'afefiloi o lo'o i totonu o le u'amea.

Fa'avasegaga Masani

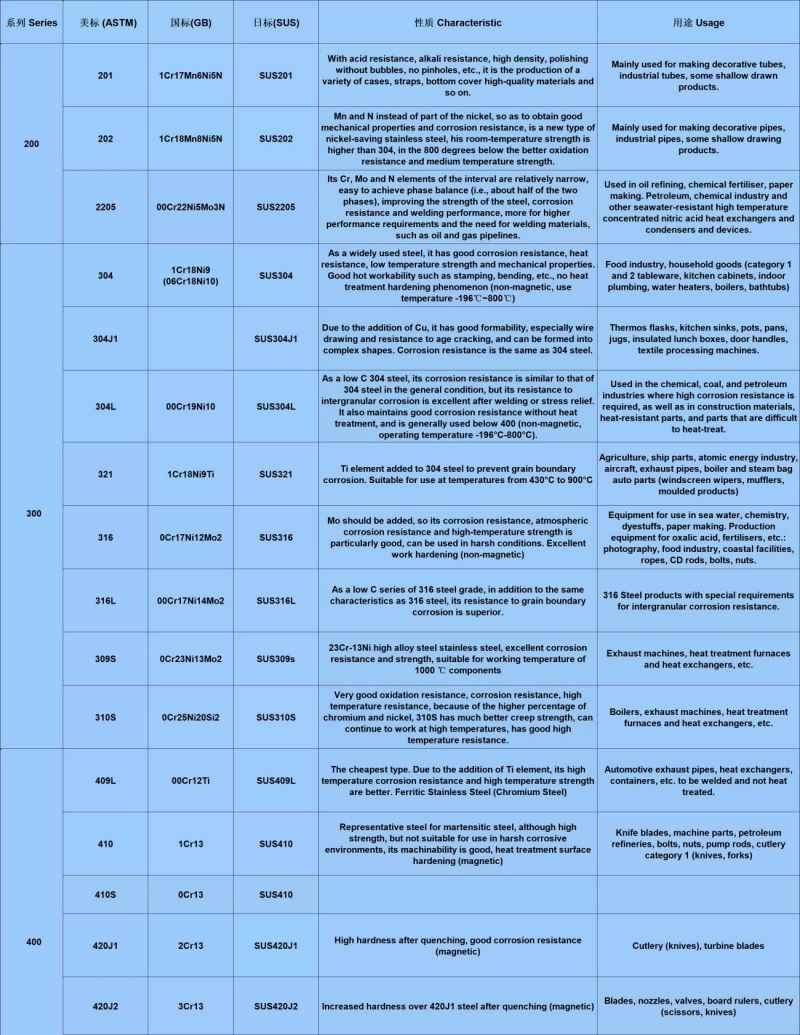

E tusa ai ma le faʻalapotopotoga o uʻamea

I se tulaga lautele, e tusa ai ma le faʻalapotopotoga o uʻamea, o uʻamea e le gaoia e vaevaeina i ni vaega se tolu: uʻamea e le gaoia austenitic, uʻamea e le gaoia ferritic ma uʻamea e le gaoia martensitic. I luga o le faʻavae o le faʻatulagaga faʻavae o uʻamea o nei vaega e tolu, o uʻamea duplex, uʻamea e le gaoia faʻamaʻaʻaina ma uʻamea uʻamea maualuga e iai le uʻamea e itiiti ifo i le 50% e maua mai mo manaʻoga ma faʻamoemoega faʻapitoa.

1. Uamea e le gaoia e Austenitic

O le fausaga o le matrix i le face-centered cubic crystal o le austenitic organization (CY phase) e pulea e le non-magnetic, e masani lava e ala i le cold working e faʻamalosia ai (ma e ono oʻo atu ai i se tulaga patino o le magnetism) o le uʻamea e le gaoia. O le American Iron and Steel Institute i le 200 ma le 300 faasologa o faʻailoga numera, e pei o le 304.

2. Uamea e le gaoia Ferritic

O le fausaga o le ferrite (o se vaega) e fa'avae i luga o le matrix i le cubic crystal e pulea e le tino, e maneta, e masani ona le mafai ona fa'ama'a'aina e ala i le fa'avevela, ae o le galue malulu e mafai ona fa'amalosia teisi ai le u'amea e le gaoia. American Iron and Steel Institute i le 430 ma le 446 mo le fa'ailoga.

3. Uamea e le gaoia e Martensitic

O le matrix o le fa'atulagaga martensitic (body-centered cubic po'o le cubic), magnetic, e ala i le fa'avevela e mafai ona fetu'una'i ona meatotino fa'amasini o le u'amea e le gaoia. American Iron and Steel Institute i le 410, 420, ma le 440 fuainumera ua fa'ailogaina. O le Martensite e iai se fa'atulagaga austenitic i le vevela maualuga, lea e mafai ona liua i le martensite (e pei o le fa'ama'a'aina) pe a fa'amālūlūina i le vevela o le potu i se fua talafeagai.

4. Uamea e le gaoia le ituaiga Austenitic o le ferrite (duplex)

O le matrix e lua-vaega o le austenitic ma le ferrite, lea o le aofaʻi o le matrix laʻititi e masani lava ona sili atu i le 15%, maneta, e mafai ona faʻamalosia e ala i le galue malulu o le uʻamea e le gaoia, 329 o se uʻamea e le gaoia duplex masani. Pe a faʻatusatusa i le uʻamea e le gaoia austenitic, o le uʻamea duplex e maualuga lona malosi, teteʻe atu i le intergranular corrosion ma le chloride stress corrosion ma le pitting corrosion e matua faʻaleleia atili.

5. Uamea e le gaoia ona fa'ama'a'aina o timuga

O le matrix o le austenitic po'o le martensitic organization, ma e mafai ona fa'ama'a'aina e ala i le togafitiga o le precipitation hardening ina ia fa'ama'a'aina ai le u'amea e le gaoia. American Iron and Steel Institute i le 600 fa'asologa o fa'ailoga numera, e pei o le 630, o lona uiga, 17-4PH.

I se tulaga lautele, e faaopoopo atu i le uʻamea uamea (alloys), e sili atu le teteʻe atu o le uʻamea e le gaoia (austenitic stainless steel) i le ele, i se siosiomaga e itiiti le ele, e mafai ona e faʻaaogaina le uʻamea e le gaoia (ferritic stainless steel), i siosiomaga e fai si ele, afai e manaʻomia le malosi tele poʻo le maʻaa tele o le meafaitino, e mafai ona e faʻaaogaina le uʻamea e le gaoia (martensitic stainless steel) ma le uʻamea e faʻamaʻaʻa ai le vai.

Uiga ma faʻaoga

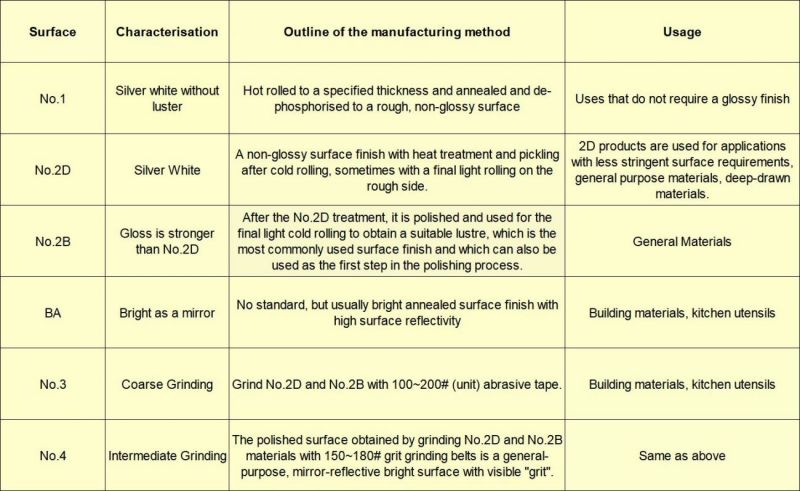

Fa'agasologa o luga

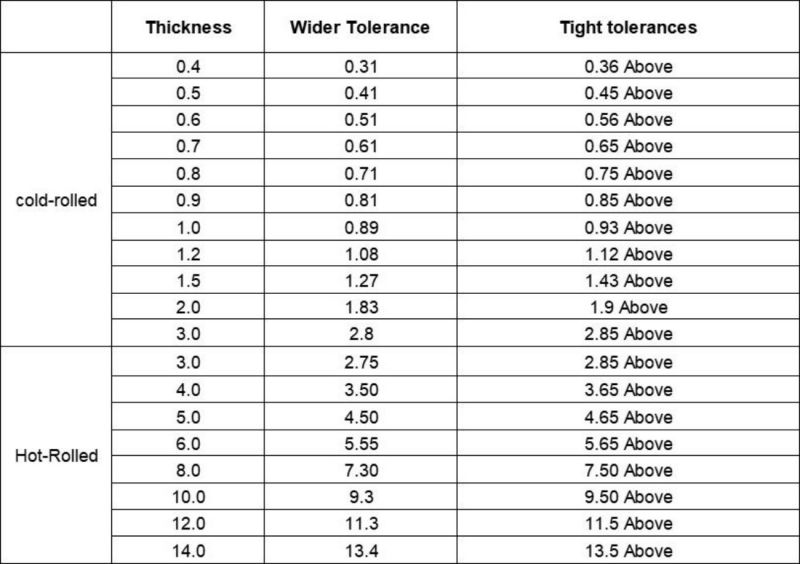

Eseesega o le mafiafia

1. Ona o le fa'agasologa o le oloina o le u'amea i totonu o le masini olo u'amea, e fa'avevela ia u'amea i se fa'aletonu la'ititi, ma i'u ai ina fa'ata'avale ese le mafiafia o le u'amea, e masani lava ona mafiafia i le ogatotonu o itu e lua o le u'amea manifinifi. I le fuaina o le mafiafia o le u'amea, e tatau ona fuaina tulafono faatonutonu o le u'amea i le ogatotonu o le ulu o le u'amea.

2. O le mafuaʻaga o le faʻapalepale e faʻavae i luga o le maketi ma manaʻoga o tagata faʻatau, e masani ona vaevaeina i ni faʻapalepale tetele ma ni faʻapalepale laiti.

V. Mana'oga mo le gaosiga ma le siakiina

1. Ipu paipa

① so'oga pito i tua o le paipa ua fa'apipi'iina mo le 100% o le siakiina o le ave po'o le UT, tulaga agavaa: RT: Ⅱ UT: Ⅰ tulaga;

② I le fa'aopoopoga i le u'amea e le gaoia, o le fa'apipi'iina o le paipa e fa'aitiitia ai le atuatuvale i le vevela;

③ le eseesega lautele o le pu o le alalaupapa: e tusa ai ma le fua fa'atatau mo le fuafuaina o le lautele o le pu o le alalaupapa: B = (S - d) - D1

Lautele maualalo o le alalaupapa o le pu: B = 1/2 (S - d) + C;

2. Togafitiga vevela o le pusa paipa:

O u'amea kaponi, u'amea u'amea maualalo ua fa'apipi'iina i se vaeluaga vaeluaina o le pusa paipa, fa'apea fo'i ma le pusa paipa o avanoa i autafa e sili atu i le 1/3 o le lautele i totonu o le pusa paipa o le ogāumu, i le fa'aogaina o le fa'apipi'iina mo togafitiga vevela e fa'aitiitia ai le atuatuvale, e tatau ona fa'agasolo le flange ma le vaega e fa'amaufa'ailogaina pe a uma le togafitiga vevela.

3. Su'ega o le mamafa

A maualalo ifo le mamafa o le mamanu o le faiga o le atigi nai lo le mamafa o le faiga o le paipa, ina ia siaki le lelei o le paipa fesuiaʻi vevela ma le fesoʻotaʻiga o le ipu paipa

① Fa'aaoga le polokalame o le atigi e fa'ateleina ai le mamafa o le su'ega i le polokalame o paipa e ogatasi ma le su'ega hydraulic, e siaki ai pe ua tafe le paipa. (Peita'i, e tatau ona fa'amautinoa o le mamafa autu o le ata tifaga o le atigi i le taimi o le su'ega hydraulic e ≤0.9ReLΦ)

② Afai e le talafeagai le metotia o loʻo i luga, e mafai ona faia se suega hydrostatic o le atigi e tusa ai ma le mamafa muamua pe a uma ona pasia, ona faia lea o le atigi mo le suega o le tafe o le ammonia poʻo le suega o le tafe o le halogen.

O le ā le ituaiga u'amea e le faigofie ona elea?

E tolu mea autū e aʻafia ai le pala o le uʻamea e le gaoia:

1. O le aofaʻi o elemene faʻafefiloi. I se tulaga lautele, o le aofaʻi o le chromium i le 10.5% o le uʻamea e lē faigofie ona ele. O le maualuga o le teteʻe atu o le chromium ma le nickel i le ele, e sili atu ona lelei, e pei o le aofaʻi o le nickel i le 304 e 85 ~ 10%, ma le aofaʻi o le chromium e 18% ~ 20%, o lea ituaiga uʻamea e lē ele e masani ona ele.

2. O le faagasologa o le fa'a'asu'iina o le u'amea e a'afia ai fo'i le tete'e atu i le 'ele o le u'amea e le'i pala. E lelei le tekinolosi fa'a'asu'iina, o meafaigaluega fa'aonaponei, tekonolosi fa'aonaponei, o le fale gaosi u'amea tetele e pulea uma elemene fa'afefiloi, e aveese ai mea leaga, ma mafai ona fa'amautinoa le puleaina o le vevela o le fa'amālūlūina o le pepa u'amea, o lea e mautu ma fa'atuatuaina le lelei o le oloa, lelei le tulaga lelei, e le faigofie ona 'ele. I se isi itu, o nisi o masini laiti o fale gaosi u'amea e tuai, o tekinolosi tuai, o le faagasologa o le fa'a'asu'iina, e le mafai ona aveese mea leaga, o le gaosiga o oloa o le a 'ele lava.

3. Siosiomaga i fafo. O le siosiomaga mago ma lelei le ea e lē faigofie ona elea, ae o le susū o le ea, timuga faifai pea, po o le ea e iai le acidity ma le alkalinity o le siosiomaga e faigofie ona elea. O le u'amea e le gaoia le 304, afai e leaga tele le siosiomaga o lo'o siomia ai e faigofie fo'i ona elea.

E faapefea ona foia ia ila ele o le u'amea e le gaoia?

1. Metotia fa'akemikolo

Fa'aaoga le sosi fa'apala po'o le suāu'u e fesoasoani ai i ona vaega ua 'ele'elea e toe fa'afo'isia ai le fa'aputuga o le chromium oxide film e toe fa'afo'isia ai lona tete'e atu i le 'ele'ele. A uma ona fa'apala, ina ia aveese uma mea leaga ma toega o le 'aisa, e taua tele le fufuluina lelei i le vai. A uma ona fa'agasolo mea uma ma toe fa'apala i masini fa'apala, e mafai ona tapuni i le suāu'u fa'apala. Mo ni vaega 'ele'elea laiti e mafai fo'i ona fa'aaoga le penisini 1:1, o le paluga suāu'u ma se ie mama e soloiese ai vaega 'ele'elea.

2. Metotia fa'amekanika

O le fa'amamāina i le oneone, fa'amamāina i le tioata po'o fasi keramika, fa'apala, fufulu ma fa'apulusina. O auala fa'amekanika e mafai ona solo ese ai le palapala e mafua mai i mea na ave'ese muamua, mea fa'apulusina po'o mea ua soloia. O ituaiga uma o palapala, aemaise lava fasi u'amea ese, e mafai ona avea ma puna o le 'ele, aemaise lava i siosiomaga susū. O le mea lea, o luga e fa'amamāina fa'amekanika e tatau ona fa'amamāina aloaia i lalo o tulaga mago. O le fa'aaogaina o auala fa'amekanika e na'o le fa'amamāina o lona luga ma e le suia ai le tete'e atu i le 'ele o le mea lava ia. O le mea lea, e fautuaina e toe fa'apulusina le luga i masini fa'apulusina ma tapuni i le vali fa'apulusina pe a uma ona fa'amamāina fa'amekanika.

O mea faigaluega e masani ona faʻaaogaina o vasega ma meatotino o uʻamea e le gaoia

1.304 u'amea e le gaoia. O se tasi lea o u'amea e le gaoia e austenitic e tele lona fa'aoga ma sili ona lautele lona fa'aaogaina, e talafeagai mo le gaosia o vaega e fa'apipi'i loloto ma paipa 'aisa, koneteina, vaega fa'atulagaina, ituaiga eseese o tino o meafaigaluega, ma isi. E mafai fo'i ona gaosia masini ma vaega e le fa'amaneta, e maualalo le vevela.

2.304L uamea e le gaoia. Ina ia foia le fa'aputuga o le Cr23C6 e mafua mai i le uamea e le gaoia 304 i nisi tulaga e iai se uiga matuia i le ele o le intergranular ma le atina'eina o le uamea e le gaoia austenitic carbon maualalo tele, o lona tulaga fa'ama'ale'ale o le tete'e atu i le ele o le intergranular e sili atu le lelei nai lo le uamea e le gaoia 304. I le fa'aopoopoga i le malosi maualalo teisi, o isi meatotino ma le uamea e le gaoia 321, e masani ona fa'aaogaina mo masini ma vaega e tete'e atu i le ele e le mafai ona togafitia i fofo fa'apipi'i, e mafai ona fa'aaogaina mo le gaosia o ituaiga eseese o tino o meafaigaluega.

3.304H uamea e le gaoia. 304 u'amea e le gaoia lala i totonu, o le vaega mamafa o le kaponi e 0.04% ~ 0.10%, ma e sili atu le fa'atinoga o le vevela maualuga nai lo le 304 u'amea e le gaoia.

4.316 u'amea e le gaoia. I le u'amea 10Cr18Ni12 e fa'avae i luga o le fa'aopoopoga o le molybdenum, ina ia mafai ai e le u'amea ona tete'e lelei i mea e fa'aitiitia ai le ele ma le tete'e atu i le pala. I le sami ma isi mea e fa'aaogaina ai, e sili atu le tete'e atu i le pala nai lo le u'amea e le gaoia 304, e masani ona fa'aaogaina mo le palaina o mea e tete'e atu i le pala.

5.316L uamea e le gaoia. O le uamea e matua maualalo le kaponi, e tete'e lelei i le ele o le intergranular, e talafeagai mo le gaosia o vaega mafolafola e pei o masini ua ueloina, e pei o masini petrochemical i mea e tete'e atu i le ele.

6.316H uamea e le gaoia. O le vaega i totonu o le uʻamea e le gaoia 316, o le vaega mamafa o le kaponi e 0.04%-0.10%, ma e sili atu le faʻatinoga o le vevela maualuga nai lo le uʻamea e le gaoia 316.

7.317 u'amea e le gaoia. E sili atu le tete'e atu i le 'ele'ele ma le tete'e atu i le tolotolo nai lo le u'amea e le gaoia 316L, e fa'aaogaina i le gaosiga o meafaigaluega e tete'e atu i le 'ele'ele o petrochemical ma organic acid.

8.321 u'amea e le gaoia. O le u'amea e le gaoia e fa'amautu i le titanium, fa'aopoopo i ai le titanium e fa'aleleia atili ai le tete'e atu i le 'ele'ele i totonu o le intergranular, ma e iai fo'i ona uiga lelei i le vevela maualuga, e mafai ona suia i le u'amea e le gaoia e le carbon austenitic e matua maualalo. I le fa'aopoopoga i le tete'e atu i le vevela maualuga po'o le hydrogen ma isi fa'alavelave fa'apitoa, e le fautuaina le tulaga lautele.

9.347 u'amea e le gaoia. Ua fa'amautu le u'amea e le gaoia austenitic i le Niobium, fa'aopoopo le niobium e fa'aleleia atili ai le tete'e atu i le 'ele'ele intergranular, tete'e atu i le 'ele'ele i le 'aisa, alkali, masima ma isi mea fa'aleaga ma le 321 u'amea e le gaoia, lelei le fa'atinoga o le fa'apipi'iina, e mafai ona fa'aaogaina o mea e tete'e atu i le 'ele'ele ma u'amea e tete'e atu i le vevela e fa'aaoga tele mo le malosiaga vevela, fanua petrochemical, e pei o le gaosiga o koneteina, paipa, fesuia'iga vevela, au, ogaumu fa'apisinisi i totonu o le paipa ogaumu ma le thermometer o le paipa ogaumu ma isi mea fa'apena.

10.904L u'amea e le gaoia. O le u'amea e le gaoia austenitic atoatoa, o se u'amea e le gaoia austenitic atoatoa na faia e Finelani Otto Kemp, o lona vaega mamafa o le nickel e 24% i le 26%, o le vaega mamafa o le kaponi e itiiti ifo i le 0.02%, e tete'e lelei i le 'ele, i totonu o 'aisa e le fa'a'okesaita e pei o le sulfuric, acetic, formic ma le phosphoric acid e matua'i tete'e lelei lava i le 'ele, ma i le taimi lava e tasi e iai sona tete'e lelei i le 'ele o le crevice ma le tete'e atu i uiga o le 'ele o le mamafa. E talafeagai mo le tele o fa'aputuga o le sulfuric acid i lalo ifo o le 70℃, ma e tete'e lelei i le 'ele i le acetic acid ma le fefiloi o le formic acid ma le acetic acid o so'o se fa'aputuga ma so'o se vevela i lalo o le mamafa masani. O le tulaga muamua ASMESB-625 e fa'atatau i le nickel-based alloys, ma o le tulaga fou e fa'atatau i le u'amea e le gaoia. E na'o le u'amea vasega 015Cr19Ni26Mo5Cu2 e fa'aaogaina i Saina, o nisi o kamupani gaosi meafaigaluega i Europa e fa'aaogaina le u'amea e le gaoia 904L, e pei o le paipa fua o le tafe mamafa o le E + H e fa'aaogaina le u'amea e le gaoia 904L, ma e fa'aaogaina fo'i le pusa uati Rolex e fa'aaogaina le u'amea e le gaoia 904L.

11.440C uamea e le gaoia. Uamea e le gaoia Martensitic, uamea e le gaoia e mafai ona fa'ama'a'a, uamea e le gaoia i le ma'a'a aupito maualuga, ma'a'a HRC57. E fa'aaogaina tele i le gaosiga o nozzles, bearings, valves, valve spools, valve seats, sleeves, valve stems, ma isi mea fa'apena.

12.17-4PH u'amea e le gaoia. O le u'amea e fa'ama'a'aina ai le fa'aputuga martensitic, o le ma'a'a HRC44, e maualuga lona malosi, ma'a'a ma tete'e atu i le 'ele, e le mafai ona fa'aaogaina mo vevela e sili atu i le 300 ℃. E lelei lona tete'e atu i le 'ele i 'ese'esega o le ea ma le 'ele'esega o le suāu'u po'o le masima, ma o lona tete'e atu i le 'ele e tutusa ma le u'amea e le gaoia 304 ma le u'amea e le gaoia 430, lea e fa'aaogaina i le gaosiga o fa'avae i fafo, lau o turbine, spools, nofoa, lima ma 'au o valves.

I le galuega fa'atino o mea faigaluega, fa'atasi ai ma mataupu tau lautele ma tau, o le filifiliga masani o le u'amea e le gaoia austenitic o le 304-304L-316-316L-317-321-347-904L u'amea e le gaoia, lea e seasea fa'aaogaina ai le 317, e le fautuaina le 321, e fa'aaogaina le 347 mo le ele i le vevela maualuga, 904L ua na'o le mea masani a nisi vaega o gaosi oloa ta'itasi, o le mamanu e le masani ona filifilia le 904L.

I le filifiliga o le mamanu o meafaigaluega, e masani lava ona i ai mea e fa'aaoga ai meafaigaluega ma mea e fa'aaoga ai paipa i taimi eseese, aemaise lava i tulaga vevela maualuga, e tatau ona tatou gauai atu i le filifilia o mea e fa'aaoga ai meafaigaluega e fetaui ma le vevela ma le mamafa o le mamanu o masini fa'agasolo po'o paipa, e pei o le paipa u'amea chrome molybdenum vevela maualuga, ae o le filifiliga o meafaigaluega e u'amea e le gaoia, e foliga mai o se fa'afitauli tele, e tatau ona e fa'afeso'ota'i le fua o le vevela ma le mamafa o mea talafeagai.

I le filifiliga o le mamanu o meafaigaluega, e masani ona feagai ma le tele o faiga eseese, faasologa, ma vasega o uʻamea e le gaoia, o le filifiliga e tatau ona faavae i luga o le faagasologa patino o le faagasologa, vevela, mamafa, vaega o loo faamamafaina, ele ma le tau ma isi vaaiga.

Taimi na lafoina ai: Oke-11-2023